Custom pouch packaging has emerged as an ideal packaging solution for various products in various industries. Different brands, such as food and beverage, electronics, and cosmetics, use this dynamic packaging option because of its sustainability and convenience. These pouches are available in different types and are created from durable materials to cater to product requirements.

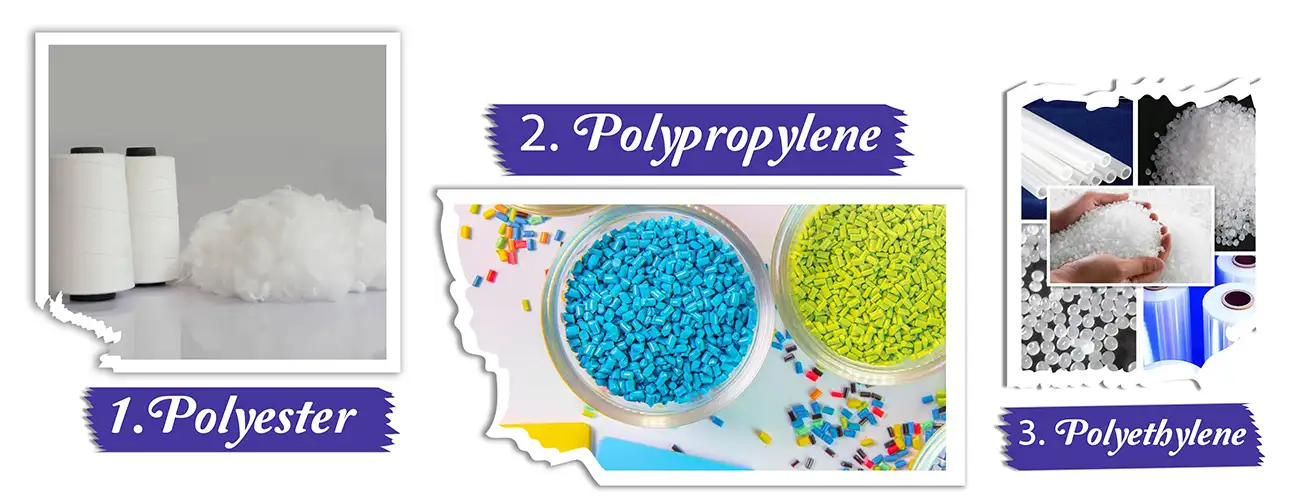

What Material Is Used For Pouch Packaging?

Plastic film material is used for pouch packaging because of customers’ preferences and product requirements. The following plastic is the ideal material to create the pouch .

- Polyester (PET): This packaging material contains barrier characteristics and strength to package different products such as beverages, pet food, and snacks.

- Polypropylene (PP): It is a heat-resistant material to package products that need the ultimate protection and visibility.

- Polyethylene (PE): It is a durable and flexible material used for stand-up sachets and pouches.

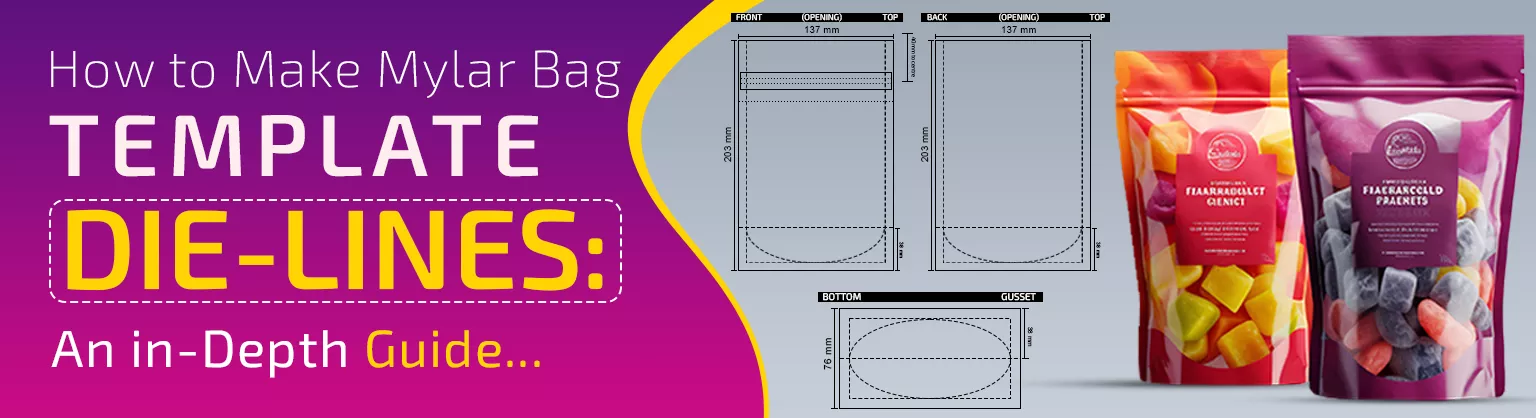

How are pouches made? These pouches are made from one or more layers of plastic film. The use of aluminum foil offers the ultimate barrier properties to package different products such as pharmaceuticals, snacks, and coffee. Moreover, metalizing polyester enhances the shelf life of products like cosmetics, candies, and chips. For more information on our mylar bags, check out our detailed blog post All About Mylar Bags.

How Many Types Of Pouches Are There?

- Stand-Up Pouches: Ideal pouches contain a flat bottom gusset to stand upright on retail shelves for branding and visibility.

- Flat Pouches: Pillow pouches are flat bags to package products such as small items, powders, and snacks.

- Spouted Pouches: The best pouches include a built-in spout to contain liquids like baby food, sauces, and beverages.

- Zipper Pouches: These packaging solutions with resealable zipper closures are easy to open and reclose.

- Retort Pouches: Retort pouches are best for shelf-stable products such as pet food.

- Gusseted Pouches: These expandable side gussets enhance the internal volume of pouches for irregular or bulky products.

- Vacuum Pouches: These pouches preserve freshness and improve the shelf life of products such as cheese and meat.

- Spice Pouches: These single-use and small pouches are best for seasoning blends and spices.

- Quad Seal Pouches: These pouches include four side seals to ensure structural integrity for products.

- Shaped Pouches: These pouches are available in distinctive shapes and sizes for promotional and marketing purposes.

- Sachets: You can use these small and single-use pouches to package personal care items, sauces, and condiments.

- Slider Pouches: These slider pouches include a sliding closure for the easiest closing and opening.

How To Measure Pouch Size?

It is important to consider that accurate measurements are necessary to ensure that your packaging fits with the products. The proper understanding of measurement will enable you to order effective packaging pouches for your brand. These three fundamentals of measurement will remain the same for different types of pouches.

- Length: Take the measurement of the pouch from the bottom to the top edge.

- Width: Measure the distance of one horizontal side to another.

- Depth: Consider the measurement for the depth of the pouch.

Why Flexible Pouches? Understanding Their Benefits

Flexible pouches are the ideal choice because of several benefits for different industries, such as personal care and pharmaceuticals.

Versatility

These are versatile packaging options available in different shapes and sizes for different products, such as solids, sem-solids, liquids, and powders. You can customize these pouches in accordance with your requirements.

Enhanced Shelf Life

Custom pouch packaging improves the shelf life of different types of products, such as pharmaceuticals and food, due to barrier properties against moisture, oxygen, and light.

Cost-Effectiveness

These are cost-effective packaging solutions as compared to metal cans and glass jars. These are also lightweight packaging options to minimize storage and transportation expenses.

Eco-Friendly Options

These are sustainable packaging options for consumers who are looking for biodegradable pouches for products. You can easily recycle these pouches to resume them later.

Space Efficiency And Improved Safety

Flexible pouch packaging is a space-efficient option for transportation and storage. Moreover, you can use this pouch packaging to enhance the safety of your precious products.

How Are Stand Up Pouches Printed?

Offset printing uses the inked image to transform from a plate to a rubber and then on the substrate. It is the ideal and high-quality technique to make the vibrant designs for the pouch packaging. However, it is a less common packaging technique for custom stand-up pouches because of its high setup expenses.

At The Custom Mylar Bags, we also offer digital printing through the implementation of electronic files to print substrate directly. This printing option ensures the fastest turnaround time with exceptional customization. Moreover, you can prefer digital printing to produce small batches with different designs. Therefore, it is also considered an economical printing for your brand.

How Do You Fill A Pouch Bag?

There are two methods of filling a pouch bag. It is your choice to prefer manual or automatic filling with their easy steps.

Manual Filling

- Ensure a clean workspace for your products.

- Gather the necessary materials.

- Open the pouch and ensure it remains open for the filling process.

- Measure the dimensions of the product and pour it into the pouch carefully.

- Analyze the fill level and seal the pouch properly.

Automatic Filling

- Set up a filling machine and calibrate settings.

- Feed empty pouches into the machine.

- Dispense the products into the pouches.

- Seal the pouch and ensure the quality check is correct.