Die cut Mylar bags are a useful packaging solution for different types of products. These bags are a blend of strength, visual appeal, and ease. Additionally, these bags are made with a strong material famous as “Mylar”. After that, these bags are cut into shapes to cater to the specific items’ shapes. Yet, these perfect shapes enhance the overall appeal of the product and protect it from damage as well. Most importantly, a wide range of industries use Mylar bags to fulfill their packaging need. Let’s discover the world of die cut Mylar bags in this complete guide!

What Are Die Cut Mylar Bags?

Did you ever imagine how your snacks, food items, and electronic gadgets look so cool? It is all the magic of die cut Mylar bags. Yes, these superb bags are specially made to meet your different needs. Also, their material keeps the freshness of your snack lock and prevents them from moisture.

When it comes to packaging of electric gadgets, these bags act like superheroes. They protect the content from harsh handling and damage. It is not over! Cut-out Mylar bags are high in demand for cosmetics, pharmaceutical, textile, automotive, and agricultural industries.

What Does Die Cut Mean in Packaging?

Die cutting refers to the process in which a die is used to cut a specific design or shape on the material. This material can be paper, cardboard, plastic, or whatever you want. Yes, this process normally prefers to give the material unique shapes or designs for particular items. Additionally, you can also read a blog about what is die cutting.

What is a die used for?

Well, the die is ideal for several purposes. Beyond cutting, the die is best for labeling and printing as well. Don’t forget the flawless final touch of the packaging becomes possible with the use of dies. How?

Some common uses of dies in packaging are as below!

-

Die cutting

In the packaging industry, the die is usually cast off for cutting, creating a unique shape or design for certain items.

-

Embossing or debossing

Dies are widely cast off to make your brand logos or text more visible. Yet, die enables the rise in material (embossing) and depth (debossing).

-

Stamp foiling

Well, to decorate the packaging and give it a professional touch, dies are perfect for stamp foiling.

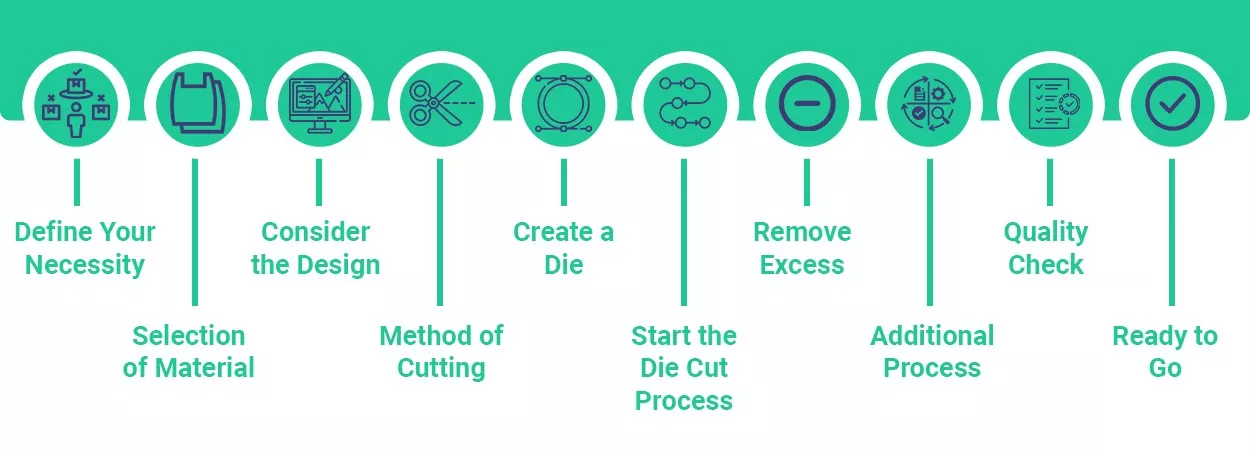

Step-By-Step Guide to Creating Custom Die-Cut Mylar Bags

Creating custom die-cut mylar bags needs a combination of design, ideas for die creation, and manufacturing process know-how. So, let’s follow the step-by-step guide and know

How to make die cut Mylar bags?

Define Your Necessity

Identify your essentials for mylar bags, including sizes, shapes, styles, patterns, etc. Most importantly, think about the window features and unique openings.

Selection of Material

Select the right material for making your bags. Make sure, the material is sturdiness, thickness, and transparency to avoid damage at the end.

Consider the Design

Consider the design for the mylar bags that not only appealing by look. But more than that, complement the die-cut shapes per your desires.

Method of Cutting

Choose the true method of cutting that aligns with your demanding shapes. Yet, remember the common die-cutting methods such as “flatbed die cutting” and “rotary die cutting.”

Create a Die

The most important part, create a die per your wants. Thus, you can contact packaging or printing companies or producers of the bags to shape up your die.

Start the Die Cut Process

Well, after creating a die, start the process. Add the Mylar films through a machine, and the die will cut the material into your favorite shapes.

Remove Excess

After all, remove the excess material that comes out with your original designs or shapes of mylar pieces.

Additional Process

According to design, you can choose an extra process such as printing. marking or labeling.

Quality Check

Check the quality of die-cut mylar bags, they meet the wants and safety standards.

Ready to Go

Lastly, when your mylar bags pass the checking process, they are ready to go for supply.

Die Cut Packaging: A Game-Changer in Product Presentation

Unconditionally, die cut packaging is a true game changer in product presentation. Why? Die cut packaging allows for the creation of unique and superb shapes and designs. Plus, with this exceptional die cut packaging brands set the stage on fire.

So, say goodbye to old and common shapes or designs such as rectangles or squares and hello to exciting die-cut wonders. Undoubtedly, attractive shapes and designs attract buyers and, better yet, increase the value of the product as well.

Ideas for Utilizing Die Cuts for Product Presentation

Showcasing of products

Die-cut packaging solutions offer a chance to showcase the products in a visually pleasing way. Whether it is a widow that gives a glimpse of the products or a customer shape that complements your item. As a result, the effective display lifts the confidence and curiosity of buyers.

Branding and recognition

Indeed, the branding element plays a vital role in improving the product presentation. hence, you can create unique shapes that align with your brand personality. Yet, adding a brand logo or message can be a smart move to create a lasting impact and build brand recognition.

Memorable unboxing experience

Unboxing also counts for overall product presentation. Therefore, if you use secure and stylish closures for making custom die cut mylar bags is a gateway to engage the buyers. So, the interactive elements or fold-out sections increase the buyer’s interest and create a memorable unboxing experience.

Highlighting the key features

Use of die cut the lead to draw attention and highlight your product features. For example, if you are selling a toy, the bottom die-cut window gives a glimpse of the toy and attracts more customers.

Exploring the Significance of Die Cut in Packaging

Die cut-in packaging is a mixture of strength and functionality. Yes, through a die-cutting process when the design or shape is ready, it is not only appealing by look. But, enhance the functionality as well.

keep in mind, that this packaging is not stay on one thing, but a huge array of items can be wrapped. On the other side, the versatility expands the material range from paper to cardboard, cardboard to plastic, and more.

Furthermore, die-cut packaging is more than just shapes or sizes. It serves a crucial role in branding and storytelling and makes your products visible in the crowd.

Benefits of Using Die-Cut Mylar Bags for Food Storage

The die cut mylar packaging bags offer several benefits for food storage. These benefits help to make your products a popular and first choice of buyers.

The primary benefit of, die-cut mylar bags is they are a wholesale option. This means that mylar bags are available at a rational rate, which makes them an ideal choice for consumers.

Where you can get wholesale die-cut mylar bags for food storage?

-

Wholesalers or manufacturer

Contact the wholesaler or manufacturer that supplies the packaging material. Yet, check out the safety terms and quality standards.

-

Packaging distributors

Discover the packaging distributors to find the packaging material for your precious food items storage.

-

Trade shows or exhibitions

Attend the trade shoes to explore the different varieties of custom die cut mylar bags for food storage.

-

Local packaging suppliers

Check out your local packaging suppliers. Don’t compromise on the quality, but stay competitive and mind your budget for the best packaging.

Lastly, you can get mylar bags from food storage of many sorts. But prefer who offer competitive price.

Things to consider before purchasing die-cut mylar bags

- Specification: ensure the mylar bags meet your requirements in terms of shape, thickness, size, etc.

- Customizable: Consider the customization options for mylar bags if you want to use them for branding purposes

- Meet regulation and safety standards: Most importantly, verify the bags meet the food safety standards.

How Die Cuts Improve Packaging’s Attractiveness?

Well, the ways are endless, but let’s note down some main ones!

Visual appeal

- Unique shape: Die cut allows you to create any shapes that look stunning in stores and align your brand status as well.

- Product visibility: Die cut is ideal for showcasing the products inside. This glimpse attracts buyers and spreads word of mouth.

Brand differentiation

- Branding: Custom die cut lets you add the logo of the brand, slogan, and other branding elements for exclusive awareness of the brand

- Innovative packaging: The die cut is a useful packaging option. Plus, it is an ideal option for inventive packaging designs and making the brand stand out from the crowd.

In the end, this die cut can adopt a window which is a smart move to attract buyers and display the sorts of items.

Summing Up

Indeed, die cut mylar bags are a useful packaging solution. Furthermore, from cosmetics or food items to electric devices, they are seamless for all types of packaging. Plus, they are frothy and protective for all items. Yet, die-cut mylar bags are the best to attract buyers and increase the overall presentation of the products.

Faqs

Can Die Cut Mylar Bags Be Used for Branding?

Yes, die-cut Mylar bags are excellent for branding.

What are Die Cut Mylar Bags?

Die-cut Mylar bags are customized packaging solutions made from durable Mylar material, precision-cut into specific shapes, offering tailored protection and visual appeal for a variety of products.

How to Create Die Cut Mylar Bags?

To create die-cut Mylar bags, design the desired shape, create a die template, and then use a die-cutting machine to cut the Mylar material precisely.

What Industries Benefit from Die-Cut Mylar Bags?

Die-cut Mylar bags benefit diverse industries, including cosmetics, pharmaceuticals, textiles, automotive, and agriculture, offering tailored packaging solutions for enhanced product protection and presentation.

Where Can I Get Wholesale Die Cut Mylar Bags for Food Storage?

Die-cut Mylar bags for food storage can be obtained from wholesalers, manufacturers, packaging distributors, trade shows, and local suppliers, ensuring cost-effective options for safe and efficient food packaging.