Die-cutting is a magnificent manufacturing procedure in the custom packaging industry. A die-cut machine is a tool for cutting packaging in various shapes and patterns. It was used in letterpress printing. Now, it has become an integral part of the evolving packaging industry, facilitating a number of businesses.

It would be best to use die-cut packaging when you are in a competitive business market and looking to stay above the competition. The die-cutting process can improve user experience and enhance brand identity. It is easy and affordable to create custom packaging in bulk for your business.

What Is Die-Cut?

Die cutting is the process of cutting packaging in different designs and sizes to align with business requirements. A die cutter with pressing is best for making custom shapes for other products. It is crucial to utilize the die perfectly to meet the custom packaging needs.

What Is a Die Cut Machine?

It is a tool to customize the size and shape of packaging material for different types of products. This machine lets you make die-cut packaging from various materials, such as fabric and paper. You can also use a personalized machine to cut the packaging material.

What Are The Different Types Of Die Cutting Machines?

Die-cutting machines are available in different types to meet specific applications and requirements.

- Automatic Die Cutting Machines

- Digital Die Cutting Machines

- Flatbed Die Cutting Machines

- Laser Die Cutting Machines

- Manual Die Cutting Machines

- Punch Press Die Cutting Machines

- Rotary Die Cutting Machines

- Waterjet Die Cutting Machines

Manual And Digital Die Cutting Machines

Digital and manual cutting machines have become superbly the best tools for cutting materials. A manual die-cutting machine is the best way to cut packaging material. This machine uses pressure and movement through the roller to cut the paper, aligning with the shape of the die.

Because of the software, the digital die-cutting tool has become more usable than a manual machine. It includes a blade rather than a steel die to cut the precise product packaging shapes. This machine enables you to create custom shapes with cartridges, computers, and mobile phones.

Die-Cutting Process With Different Functions

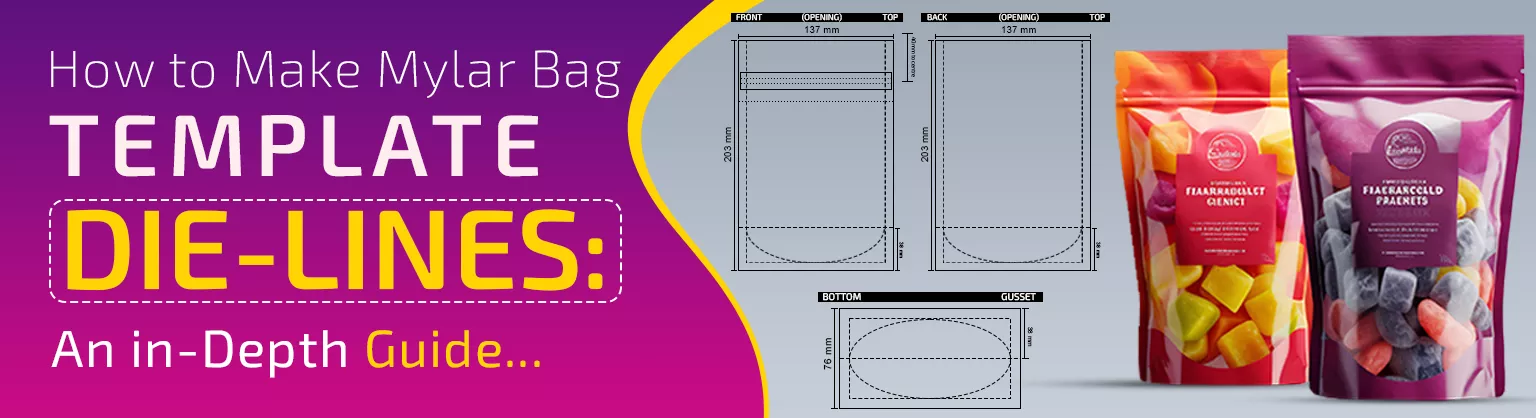

Due to different manufacturing methods and advanced technology, the die-cutting process has become a cost-effective solution for businesses. It enables you to create custom die-cut bags, such as die cut mylar bags with logos. Computer-aided design (CAD) is recommended for digitally outlining business.

A decline blends on the surface of the sideboard through the different laser cutters for the outline to cut a package. This outline lets you map the bleed, cut, and fold lines to start the die-cutting procedure smoothly. The material is usually placed on die boards for perfect placement and less movement for precise and smooth cutting.

Important Functions:

A die-cutting procedure consists of the following functions:

- Creasing: It is a process of cutting a fold line for the packaging.

- Perforating: The procedure ensures minor cuts for the flexible packaging tearing.

- Scoring: The partial cutting of the specific area of packaging.

- Through Cutting: Cutting right through the packaging material.

Every function has a specific purpose for different custom die-cutting designs. The creasing function is best for creating corrugated packaging. You can also use rubber pieces and foam to strike the steel rules to bounce the die off the corrugated board. The crease lines also ensure the most effortless folding. Therefore, you can consider pressing the die-cutting machine to cut shapes from the packaging material with different functions.

Top Die Cutting Methods

The different methods allow you to use the machine with other functions to cut the packaging material. Let’s explore the various types of die-cutting methods.

- Blanking: It is a method of slicing the flat material from the exterior edge through the clipping.

- Broaching: It’s necessary to use the large cutting teeth to cut the materials for packaging.

- Coining: You must create circular holes in the packaging material through the pressurization force.

- Drawing: It is a technique of creating long and lean die-cut packaging.

- Forming: You can use the raw material in tandem to create rounded cylindrical shapes.

What Are The Different Ways To Use Die Cuts?

- Cardmaking is a way to incorporate intricate designs, elegant shapes, and decorative elements.

- Scrapbooking is a fabulous way to create cohesive themes and embellish pages.

- Die cuts are useful for creating home decor items such as shadow boxes, banners, and wall art.

- Create invitations, party favors, and table decor for party decorations.

- Improve gift wrapping with the accurate use of die cuts.

Different Finish Options For Die-Cutting Packaging

Die-cutting ensures a distinctive experience for businesses to impress customers with the packaging. Custom packaging must speak volumes about your business while ensuring the luxurious appearance of the different products. You need to have enough funds to create the ideal packaging with the involvement of a die-cutting process.

There are different finishing options to utilize in this die-cutting procedure. These finishes make your brand more visible to consumers by giving it an excellent appearance. Let’s explore the different finishing choices for printing dies to attract potential customers.

- Foil Stamping

- UV Printing

- Debossing/Embossing

Purpose Of Using A Dieline For The Creation Of Custom Die Cut

A decline is crucial to outline the process for smoothly creating custom-shaped mylar bags. This decline offers the ultimate convenience for cutting packaging with different customization requirements.

Start Using The Printing Dies in The Custom Packaging Industry Regularly

Cutting the packaging material is an expensive but one-time investment. This process reduces the long-term costs of creating custom packaging repeatedly. You have complete flexibility in developing die-cut packaging in bulk with a single press. Moreover, it is a cost-effective solution for your business.

Die Cut History

History shows that die is a word from the English word ‘de’ and the Latin word ‘datum.’ In 1300, it was a casting approach for metal coins. In 1800, it started to be called “created by machine.” A complete guide on die-cut Mylar bags allows you to understand and make the die-cut quickly and perfectly.

Conclusion

This die-cut process allows you to understand the manual and digital machines used to make die-cut packaging for your brand’s distinctive identity. Different functions and methods, with finishing options, are available to customize the packaging according to business needs.